You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Walnut Hollowbody Build

- Thread starter Elias Graves

- Start date

Elias Graves

Common misfit

There's three ways you can go: Seal and Sand, which of course means one or two rounds of sealing and sanding, or grain filler, which means you'll need to stain the filler to blend in, or just sealer which means you'll need a shit-ton of sanding and recoating and resanding, unless you want pore-dimples, which, of course will eventually collect hand crud (technical term).

I have a plan already. I'll stain it and use tru oil.

After a few coats, you wet sand with more tru oil as the lubricant. The sawdust gets worked into the pores then sealed in place when the varnish dries.

Trying to stay simple on the finish work this time.

BoomBoomBigelow

Genius of Love

Sounds legit.I have a plan already. I'll stain it and use tru oil.

After a few coats, you wet sand with more tru oil as the lubricant. The sawdust gets worked into the pores then sealed in place when the varnish dries.

Trying to stay simple on the finish work this time.

Elias Graves

Common misfit

A nice dark stain like so.

Elias Graves

Common misfit

Ran the neck board through the planet and brought it down to 2 1/4" thick. I now have two flat sides. Time to work on the other two sides.

Elias Graves

Common misfit

Planet.

Elias Graves

Common misfit

As you can see, the sides aren't square to the faces.

Elias Graves

Common misfit

This board is right at 2" thick. It will become the three piece back.

This board will become the top.

This board will become the top.

Elias Graves

Common misfit

Luckily you really don't need the sides to be square for the neck...one square side for the fingerboard and the rest is carved...

...does the face board have a lot of checking or is that just the way you took the pic?

Must be the pic. It's smooth out of the plane now.

These three will be the body. They are too wide right now, so ill trim each one down to about 5" wide or a hair under. Removing the sapwood should do it.

They measure 1 15/16" thick.

These, destined for joinery as they are, must have square sides.

Elias Graves

Common misfit

And these two will be the top. All together, it comes in about 3 1/4" thick. That will come down to about 3" even when it's done.

Elias Graves

Common misfit

Something to hint at my inspirations for this one.

Elias Graves

Common misfit

Elias Graves

Common misfit

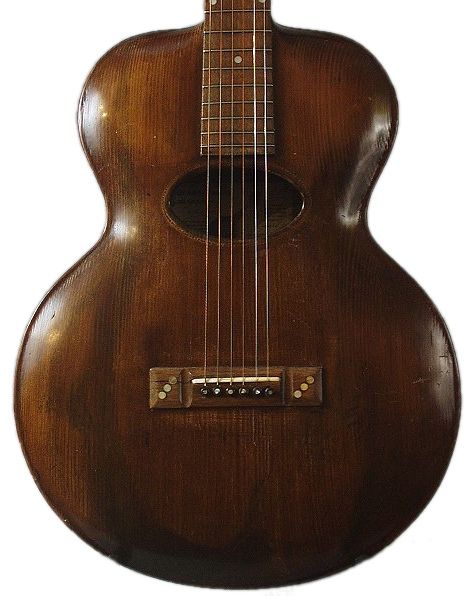

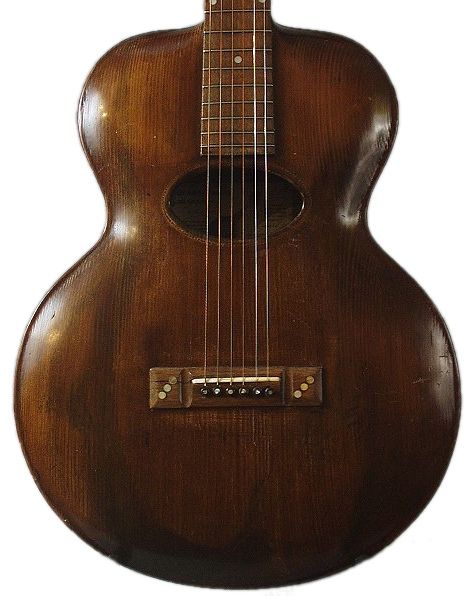

And it's acoustic, non-cutaway cousin

Elias Graves

Common misfit

Ah, I finally found the one I was looking for. It's an 1898 Orville Gibson model OH. All solid carved archtop, which he patented, btw. (His one and only patent)

Elias Graves

Common misfit

Damn, talk about your volute! And people got pissed at Gibson in the 70s over a tiny bump!

Elias Graves

Common misfit

And it's a pancake body to boot!

Elias Graves

Common misfit

So I got to pricing having my fretboard made vs making it myself, I need to see first if I CAN do it myself.

With no rosewood handy, I grabbed a stick o walnut. It's pretty hard; ought to hold a fret. The main thing I need to see is if I can cut a square line and whether this is the right saw.

Looks good, eh ?

No.

Observe the little gap on the left side of the fret.

The saw is too big.

Popped right out.

That's my smallest saw, I think.

With no rosewood handy, I grabbed a stick o walnut. It's pretty hard; ought to hold a fret. The main thing I need to see is if I can cut a square line and whether this is the right saw.

Looks good, eh ?

No.

Observe the little gap on the left side of the fret.

The saw is too big.

Popped right out.

That's my smallest saw, I think.