irishstu

really experienced

DIY Stratocaster Build - hand tools only pt 1

Morning, all. I thought that, since Mark is trying to promote a kind of DIY/lutherie thing at the moment, I would take the opportunity to post about my DIY strat build.

Unlike some of the other excellent builds from the likes of

73Custom/GuitarNoobie, this one was made with mostly handtools and a total absence of previous experience. I thought it would be good to post about it to show you that pretty much anyone can make an electric guitar.

I learnt a LOT making this guitar and if I did it again, I would do quite a few things differently. However, I did end up with a very fine guitar and after a recent upgrade, it is currently my go-to guitar.

One of the beautiful things about attempting a project like this is that little things like setups, pickup swaps, etc., seem like a piece of cake afterwards. I would really encourage you to try something like this if you have been thinking about it.

Please do ask me questions along the way, because, like I said, I learnt a lot and would maybe advise people to attempt some of the steps in a slightly different way.

Anyway, on with the show...

OK, the first thing I needed was to get my hands on a reference Strat-like guitar (at the time I did this, there was very little info online and strat plans were hard to come by, although now I suspect it's a piece of cake).

It's not hard to get your hands on a Strat copy, and right enough, a friend of a friend happened to have one. I borrowed it and drew an outline around it on a big piece of paper.

Doing this on paper was a bad move, I now realise. A much better option would have been to trace it onto card. In fact, if you're really serious about this, tracing it onto a piece of thin wood would be even better.

OK, so now I had my outline and a few measurements. The next thing was to find a nice big bit of wood. As it happened, the same friend of a friend worked in the timber industry and was able to source me some.

Now I had to figure out which wood to ask for.

I did some investigation and found that real Strats were made of ash or alder. My friend of a friend (the one in the timber industry) informed me that he could more easily source some ash, so I happily gave him the dimensions I needed. The wood had to be 45mm thick and at least as big as the outline template I had made. A little bit extra around the edges gave me some room for avoiding blemishes, etc., or placing them where they would not be seen (like under the scratchplate, for example).

Here's a photo of the chunk of wood as it arrived. In fact it is two pieces glued together. It arrived already glued, and importantly, had been well dried out.

Unfortunately this wasn't the "swamp" ash used in most real Strats, but the ash that (I think) is more commonly used in the construction of baseball bats (northern ash). That stuff is solid! It also weighs a tonne. This was something I wasn't going to realise until I finished the guitar and picked it up for the first time. Anyway, learn from my mistake; get "swamp" ash. Luckily the ash I got still gives great tone.

So anyway...

Now that I had my outline and my chunk of wood, it was time to get cutting. I was very excited about this, because I was finally going to get my hands dirty. Firstly I taped the paper outline to the wood (trying a few different positions to minimise/hide blemishes in the wood). Here's what I came up with:

Now there are many reasons why the paper-taped-to-wood option was not a good way to go about this, but I won't go into too much detail. I'll just say that you should look into using card instead of paper, and drawing an outline around it onto the wood, instead of sticking anything to it. Now... you see that great big knot to the left of the photo? That's the sort of blemish I was happy to remove.

Did I mention that I had hardly any tools? I managed to borrow an electric jigsaw for this next part, and I broke the bank and bought a couple of clamps to hold the block of wood down while I was cutting it. Here's what the edge will look like after cutting it out with an electric jigsaw. (Lower edge only. I had already smoothed the rest before I remembered to take this photo.):

My advice here is not to cut too close to the outline, as the jigsaw tends to not cut exactly downwards. This means it could cut closer at the bottom than at the top. Also, erm... I know it should go without saying, but remember to move your block of wood from time to time, so that you don't cut into your table/workbench. Or in my case.... the dining room table (yeah, no kidding).

Morning, all. I thought that, since Mark is trying to promote a kind of DIY/lutherie thing at the moment, I would take the opportunity to post about my DIY strat build.

Unlike some of the other excellent builds from the likes of

73Custom/GuitarNoobie, this one was made with mostly handtools and a total absence of previous experience. I thought it would be good to post about it to show you that pretty much anyone can make an electric guitar.

I learnt a LOT making this guitar and if I did it again, I would do quite a few things differently. However, I did end up with a very fine guitar and after a recent upgrade, it is currently my go-to guitar.

One of the beautiful things about attempting a project like this is that little things like setups, pickup swaps, etc., seem like a piece of cake afterwards. I would really encourage you to try something like this if you have been thinking about it.

Please do ask me questions along the way, because, like I said, I learnt a lot and would maybe advise people to attempt some of the steps in a slightly different way.

Anyway, on with the show...

OK, the first thing I needed was to get my hands on a reference Strat-like guitar (at the time I did this, there was very little info online and strat plans were hard to come by, although now I suspect it's a piece of cake).

It's not hard to get your hands on a Strat copy, and right enough, a friend of a friend happened to have one. I borrowed it and drew an outline around it on a big piece of paper.

Doing this on paper was a bad move, I now realise. A much better option would have been to trace it onto card. In fact, if you're really serious about this, tracing it onto a piece of thin wood would be even better.

OK, so now I had my outline and a few measurements. The next thing was to find a nice big bit of wood. As it happened, the same friend of a friend worked in the timber industry and was able to source me some.

Now I had to figure out which wood to ask for.

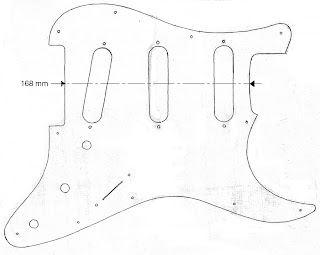

I did some investigation and found that real Strats were made of ash or alder. My friend of a friend (the one in the timber industry) informed me that he could more easily source some ash, so I happily gave him the dimensions I needed. The wood had to be 45mm thick and at least as big as the outline template I had made. A little bit extra around the edges gave me some room for avoiding blemishes, etc., or placing them where they would not be seen (like under the scratchplate, for example).

Here's a photo of the chunk of wood as it arrived. In fact it is two pieces glued together. It arrived already glued, and importantly, had been well dried out.

Unfortunately this wasn't the "swamp" ash used in most real Strats, but the ash that (I think) is more commonly used in the construction of baseball bats (northern ash). That stuff is solid! It also weighs a tonne. This was something I wasn't going to realise until I finished the guitar and picked it up for the first time. Anyway, learn from my mistake; get "swamp" ash. Luckily the ash I got still gives great tone.

So anyway...

Now that I had my outline and my chunk of wood, it was time to get cutting. I was very excited about this, because I was finally going to get my hands dirty. Firstly I taped the paper outline to the wood (trying a few different positions to minimise/hide blemishes in the wood). Here's what I came up with:

Now there are many reasons why the paper-taped-to-wood option was not a good way to go about this, but I won't go into too much detail. I'll just say that you should look into using card instead of paper, and drawing an outline around it onto the wood, instead of sticking anything to it. Now... you see that great big knot to the left of the photo? That's the sort of blemish I was happy to remove.

Did I mention that I had hardly any tools? I managed to borrow an electric jigsaw for this next part, and I broke the bank and bought a couple of clamps to hold the block of wood down while I was cutting it. Here's what the edge will look like after cutting it out with an electric jigsaw. (Lower edge only. I had already smoothed the rest before I remembered to take this photo.):

My advice here is not to cut too close to the outline, as the jigsaw tends to not cut exactly downwards. This means it could cut closer at the bottom than at the top. Also, erm... I know it should go without saying, but remember to move your block of wood from time to time, so that you don't cut into your table/workbench. Or in my case.... the dining room table (yeah, no kidding).

Last edited by a moderator: